Coconut shell charcoal has become increasingly popular due to its efficiency, sustainability, and versatility. If you’re curious about creating a clean, eco-friendly fuel source at home, learning how to make charcoal from coconut shell is an excellent way to start. This guide will walk you through a simple method to make coconut shell charcoal at home, saving costs while staying eco-friendly.

Why Choose Coconut Charcoal?

Coconut charcoal offers several benefits that make it stand out among other types of charcoal.

- High Calorific Value and Long Burn Time: Coconut shells produce charcoal with a high heat output that burns long, making it perfect for grilling or home heating.

- Eco-Friendly and Sustainable: Using coconut shells, which are often discarded as waste, helps reduce environmental impact. This makes it a truly eco-friendly charcoal.

- Low Smoke and Odor: Coconut charcoal produces minimal smoke and odor, preserving the natural taste of grilled foods.

By choosing coconut charcoal, you not only gain a high-quality fuel source but also contribute to sustainable waste management practices.

Materials and Tools Needed

Before starting the process, gather the following:

- Coconut charcoal shell: Clean, dried coconut shells. These can be sourced from local suppliers or trusted charcoal manufacturers.

- Binding agent (optional): Some methods use a small amount of starch or clay to help form briquettes.

- Pressing mold: For shaping briquettes or cubes.

- Grinding tools: A mortar, grinder, or other tools to crush the shells.

- Kiln or metal drum: For carbonization, which converts shells into charcoal.

It’s also important to check the coconut charcoal price locally to decide whether making it at home is more cost-effective than purchasing ready-made products.

Check coconut charcoal prices in the following article: Coconut Charcoal Price Update in the 2025 Charcoal Market

Steps to Make Coconut Charcoal

Step 1: Collect and Clean Coconut Shells

Start by collecting coconut shells from your kitchen, local markets, or suppliers. Make sure they are free from any leftover coconut meat or fibers. Cleaning is essential to reduce smoke and ensure even burning. After washing, dry the shells in sunlight or an oven until completely moisture-free. Proper drying is critical because moisture can hinder the carbonization process and produce excessive smoke.

Step 2: Grind the Coconut Shells

Once the shells are dry, crush them into smaller pieces using a grinder or mortar. For making natural briquette charcoal, you may need finer particles to mix with a binding agent. The grinding process affects the quality and uniformity of your final product. Finer particles produce denser briquettes that burn longer and more consistently.

Step 3: Form Briquettes or Cubes

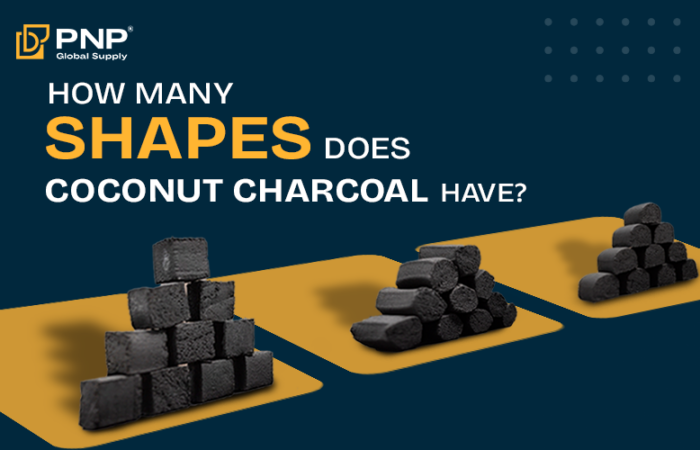

After grinding, it’s time to shape the charcoal. Using molds, press the material into cylinders for coconut briquette charcoal or small squares for coconut charcoal cubes. This step is crucial for storage, transportation, and efficient burning. Proper pressing ensures that the charcoal holds its shape, making it easier to handle and use in grills or stoves.

Tips for Shaping:

- Apply even pressure to avoid cracks.

- If using a binding agent, mix thoroughly to ensure the briquette holds together.

- Try different sizes depending on your cooking needs: larger briquettes for long cooking times and cubes for smaller, quick heat.

Step 4: Carbonization (Charcoal Making)

Carbonization is the process that transforms coconut shells into usable charcoal. It requires controlled heating in a low-oxygen environment to prevent combustion.

Carbonization Steps:

- Place the shaped shells or briquettes in a kiln, drum, or metal container.

- Heat gradually, starting with a low temperature to remove moisture.

- Maintain a steady temperature until the shells turn black and all volatile matter is burned off.

- Ensure minimal oxygen exposure to avoid turning the shells to ash.

Proper carbonization produces high-quality coconut charcoal that is dense, burns long, and produces little smoke.

Step 5: Cooling and Storage

After carbonization, allow the charcoal to cool naturally in the container before handling. Avoid contact with air while it is still hot to prevent oxidation or spontaneous combustion.

Store the finished charcoal in dry, airtight containers to preserve its quality and prevent moisture absorption. Well-stored coconut briquette charcoal or coconut charcoal cubes can last months without losing burning efficiency.

Tips for Making High-Quality Coconut Charcoal

- Use only clean, dry shells to reduce smoke.

- Press the charcoal tightly to improve burning performance.

- Carbonize at stable temperatures for even quality.

- Use molds to achieve consistent shapes, making the charcoal easy to handle.

- Consider making eco-friendly charcoal at home from leftover shells to minimize waste.

Comparing Homemade vs Market Products

Making charcoal at home can save costs, but it requires time and effort. Checking the coconut charcoal price locally helps determine the best option. Ready-made products from trusted charcoal manufacturers can save time and guarantee consistent quality, especially if you need natural briquette charcoal, coconut charcoal cubes, or pre-shaped coconut briquette charcoal.

Practical Applications

Coconut charcoal is highly versatile:

- BBQ Grilling: Minimal smoke and long burn time make it ideal for grilling meat, seafood, and vegetables.

- Home Heating: Efficient burning provides consistent heat for stoves or small heaters.

- Eco-Friendly Cooking: Using eco-friendly charcoal reduces reliance on wood charcoal and supports sustainable practices.

Buying and Sourcing Raw Materials

If you prefer not to start completely from scratch, you can purchase partially processed shells from charcoal manufacturers. They may offer pre-crushed shells, briquettes, or cubes ready for carbonization.

When buying, compare prices to make sure you are getting good value:

- Check the coconut charcoal price per kilogram.

- Ensure the supplier uses clean, natural shells.

- Choose products that meet your desired shape and size.

PNP Charcoal provides high-quality, clean, and long-lasting coconut charcoal. Visit our website: pnpcharcoal for more details and pricing.

Safety and Maintenance

- Store charcoal in dry, sealed containers.

- Keep away from children and flammable materials.

- Use gloves when handling hot or freshly carbonized charcoal.

- Avoid storing in direct sunlight or humid areas to maintain quality.

Conclusion

Learning how to make charcoal from coconut shell at home is both cost-effective and environmentally friendly. By following this detailed guide, you can produce high-quality coconut charcoal. Whether you choose to make it yourself or source from trusted charcoal manufacturers, using coconut shell charcoal provides a clean, long-lasting fuel source that is perfect for grilling, cooking, or heating. Embrace sustainable practices and enjoy the benefits of eco-friendly charcoal in your home today.

________________________________

Contact us for more information

Facebook: PNP Charcoal

Instagram: PNP Charcoal

Email: info@pnpglobalsupply.com