This article explains “How is charcoal made?”. From the selection of correct woods to carbonization procedure, this article will direct you ahead in every step. This article might enable you to understand hardwood charcoal, its manufacturing and benefits better.

How is Charcoal Made?

Basic Process

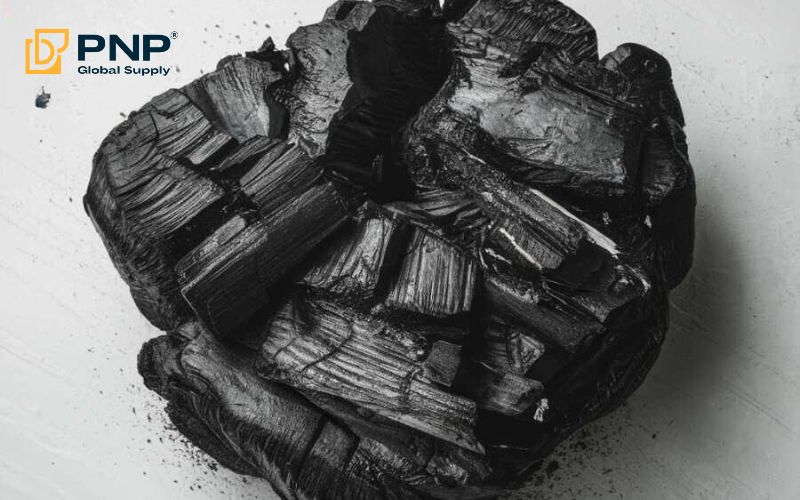

In charcoal production, the process begins with burning wood or organic matter in a low-oxygen environment. This burning under control, called carbonization, helps remove elements that can turn volatile such as water, methane, and tar. The outcome is a carbon-rich substance that makes a good base for high-quality charcoal.

Comparing Conventional and Contemporary Techniques

Conventional charcoal production methods such as pit kilns are straightforward and inexpensive but often lead to poor charcoal quality with varying carbon content. They do not have the precision needed in contemporary applications hence they less effective when compared to the latest industrial techniques.

Types of Wood and Materials Used

In the production of charcoal, the wood species and other materials play a significant role in determining quality and characteristics. For instance, hardwoods like oak, hickory, and maple are mostly used for producing lump charcoal owing to their high density and carbon content. Moreover, there are places where coconut shells among other materials serve as an alternative since they are very plenty.

Types of Materials

The types of charcoal produced from different materials will not be the same in any way. The most commonly used ones are hardwoods; however, even other organic materials such as coconut shells can be carbonized to get finer charcoal.

Charcoal Varients

The actual types of charcoal include lump charcoal and briquettes. Pure wood does make lump charcoal which burns naturally without any additives hence valued by many people. However, some use residuals instead of pure wood alongside additives resulting in uniformity as far as their shapes and times for burning are concerned, such briquettes could have binders or other chemicals too.

Lump Charcoal vs. Charcoal Briquettes

Lump Charcoal

Lump charcoal is truly composed of hardwood, thus making it a completely natural product without any additives. As its shapes are not regular they may influence how long it will burn (burning time) and how much heat will be distributed throughout. However, lump charcoal burns at higher temperatures while producing less ash; hence those who want a more authentic grilling experience can choose Lump charcoal.

Charcoal Briquettes

Charcoal briquettes are produced by mixing wood by-products such as sawdust with binders and fillers so that they take specific uniform shapes to ensure they burn uniformly. Even though they have come to be preferred by many consumers, unlike lump charcoals known for their clean burning properties; this type of charcoal has more odor from additional chemicals added during its manufacturing.

Historical Production Methods

Ancient Charcoal Production (4,000 BC)

Charcoal making can be traced back to about 4,000 BC when the early societies began to realize its importance in metalworking and cooking. This involved straightforward techniques like placing firewood in heaps and then covering it with mud or clay so as to check oxygen supply thus making it burn slowly and give off charcoal.

Evolution Of Methods

Overtime, the process of charcoal production evolved from the use of earth mounds for kilns that were so laborious and ineffective into more advanced ways. The introduction of brick kilns finally gave way to contemporary industrial methods which allowed better control over carbonization yielding higher quality and uniform charcoal products.

What’s Really in Your Charcoal?

Additives in Charcoal

The role of additives in charcoal such as heat fuel materials, binding agents, borax, limestone, and sodium nitrate cannot be underestimated when it comes to improving performance and consistency. The heat fuel materials aid in enhancing the burn efficiency while binding agents make sure that briquettes maintain their shape. Borax and limestone facilitate ignition and reduce the amount of ash produced while sodium nitrate can enhance the burning temperature. These are the main additives found in most Charcoal Briquettes to ensure the regularity and longevity of the fire glaze.

Making Your Own Charcoal

Equipment Needed

- Metal Barrel: Utilized for the carbonization method, sometimes provided with a cover for regulating oxygen course and maintaining even burning.

- Hardwood: Necessary to produce charcoal of good quality, chosen according to its density and carbon level.

- Kindling: Tiny pieces that ignite quickly and help light up the flame in the metal barrel.

- Fire Protection: Protective equipment including gloves or masks to withstand heat and smoke while making charcoal.

Process

- Starting the Fire: Ignite kindling inside the metal barrel to create an initial flame.

- Adding Hardwood: Once the kindling is burning, gradually add hardwood pieces to the barrel.

- Smoldering: Allow the wood to smolder in a low-oxygen environment, which helps in carbonizing the wood.

- Finishing: After several hours, carefully remove the barrel from heat and let the charcoal cool before use.

Discover Premium Charcoal from PNP Charcoal

PNP Charcoal is a well-known name in the industry established in 2015. It deals with the manufacturing and supply of top-notch charcoal that satisfies customers’ needs through high-quality products. With years of experience in the area, PNP Charcoal strives to uplift the Vietnamese charcoal sector and help get local products into overseas markets.

Charcoal FAQs

For how long does charcoal last?

In a cool, dry place, charcoal may last for several years.

What can charcoal dust be used for?

Garden fertilization and water filtration are among the numerous uses of charcoal dust.

What happens if charcoal gets wet?

Wet charcoal becomes less effective and may not ignite easily or burn well.

What is the environmental impact of charcoal production?

Unsustainable charcoal production can cause deforestation as well as environmental pollution.

Conclusion

To sum up, the knowledge of “How is lump charcoal made?” unveils an interesting procedure that involves the combustion of hardwood in an atmosphere low in oxygen for production of a high carbon fuel. Each stage from choosing good hardwoods to carbonization processes contributes towards charcoal effectiveness and its quality. If you are looking for superior hardwood charcoal, get in touch with PNP Charcoal in order to purchase premium products that adhere to very high-quality requirements.