When people think of charcoal, the first images that come to mind are BBQ grills, roasted meat, and cozy family gatherings. Yet behind every piece of charcoal is a fascinating journey of craftsmanship, precision, and care. Today, we invite you to explore PNP’s charcoal factory in Binh Phuoc, Vietnam, and see how hardwood is transformed into premium charcoal trusted by customers worldwide.

With more than 10 years of experience, PNP Charcoal has become a leading manufacturer in Vietnam. The factory not only produces high-quality charcoal but also opens its doors for visitors to witness every step of the process. This transparency reflects PNP’s confidence in quality and its commitment to customers.

Inside PNP’s Charcoal Factory

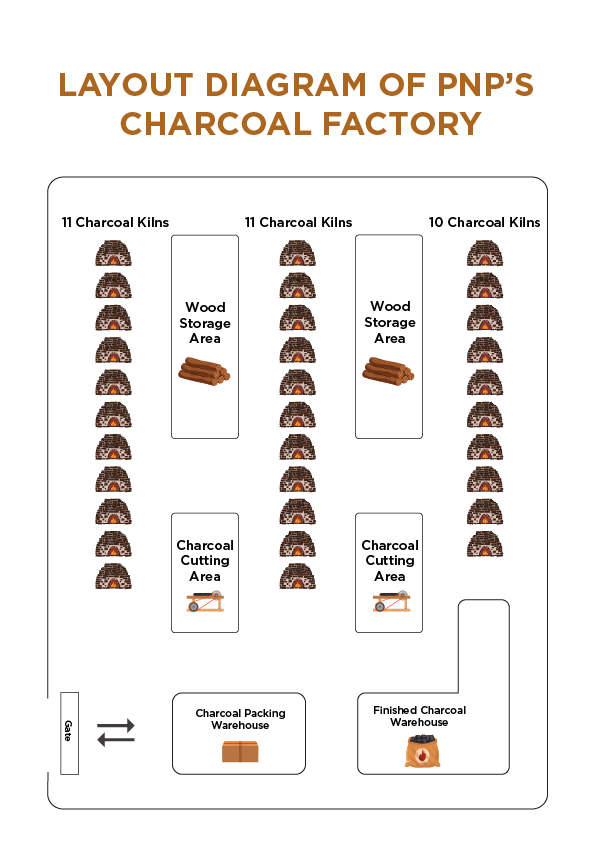

The factory combines traditional techniques with efficient organization. It includes:

- Three kiln zones with more than 30 charcoal kilns

- Two wood storage areas where raw materials are kept

- Two cutting zones for preparing logs

- A large finished-goods warehouse for safe storage

- A packing warehouse dedicated to sorting and packaging orders

PNP focuses on producing coffee wood charcoal, khaya charcoal, longan charcoal, and mixed hardwood charcoal. Each variety has its own strengths – from long burning time to high heat and clean smoke – but all share the same hallmark of consistency and quality.

Area 1: Wood Storage

The first stop is the wood storage area. Here, hardwood logs are carefully selected and stacked in order. The type and quality of wood directly influence the final charcoal. For example, longan wood creates dense charcoal with strong heat, while coffee wood is known for burning longer.

This stage is crucial in the charcoal carbonization process, because only the right raw materials can produce premium results.

Area 2: Cutting Zone

From storage, the logs are moved to the cutting zone. Each piece of wood is trimmed to a length of about 45–46 cm. This standard size ensures that the logs fit perfectly into the kilns and carbonize evenly.

While it may seem like a simple step, precise cutting improves efficiency and reduces waste. Skilled workers combine traditional methods with tools, and sometimes with support from modern equipment such as the wood cutting machine, to maintain uniformity and speed.

Area 3: The Kilns

Next comes the most important area: the kiln zones. With more than 30 kilns on site, this is where the transformation truly happens.

Wood is loaded into the kilns and undergoes the charcoal carbonization process. In this controlled, oxygen-limited environment, moisture and volatile substances are slowly removed, leaving behind pure carbon. Depending on the wood type and technique, this process can take several days.

Visitors are often fascinated by this stage because it shows exactly how to manufacture charcoal on a large scale. The result is dense, clean-burning charcoal that lasts longer than ordinary alternatives.

Area 4: Finished Goods Warehouse

Once the carbonization is complete, the charcoal is transferred to the finished goods warehouse. Proper charcoal storage is essential to maintain quality.

At PNP, the warehouse is well-ventilated and shaded, keeping the charcoal safe from moisture and sunlight. This careful handling ensures that every order delivered to customers maintains its original density and performance.

Area 5: Packing Warehouse

The final step of the tour is the packing warehouse. Here, the charcoal is sorted, sized, and packaged according to each customer’s needs.

- For wholesale buyers, bulk lump charcoal is packed into durable woven bags or loaded directly into shipping containers.

- For wholesale importers supplying restaurants, supermarkets, or retail chains, charcoal is packed into smaller packages. Depending on requirements, PNP offers packaging in offset cartons, flexo cartons, or OPP bags.

This flexibility allows PNP to serve a wide range of clients worldwide. On average, the factory produces up to 2,000 tons of charcoal per month, which are then exported to Asia, Europe, the Middle East, and the United States.

Here, customers can also discuss details such as packaging style, volume, or even price charcoal for large orders.

Guests can receive charcoal samples for testing. The samples let customers experience PNP’s quality directly – a clear demonstration of the company’s confidence in its products.

Why Visit a Charcoal Factory?

Taking part in a tour at PNP’s factory offers several benefits:

- Understand the process clearly: From wood storage to kilns and packaging, you see every step.

- Evaluate quality directly: Seeing production firsthand builds trust in the brand.

- Discuss your needs: Packaging, bulk orders, and shipping options can be customized.

- Enjoy hospitality: Free transport, meals, and product samples make the trip informative and enjoyable.

Join PNP’s Charcoal Factory Tour

Whether you are a wholesaler, distributor, restaurant owner, or simply a grilling enthusiast, visiting PNP’s charcoal factory in Binh Phuoc is an experience worth having.

With more than 10 years of expertise, PNP Charcoal guarantees consistent quality, excellent service, and a transparent manufacturing process.

Contact PNP today to join a free factory tour, receive product samples, and discover why PNP’s charcoal is trusted worldwide.

Discover our charcoal factory through this short video:

________________________________

Contact us for more information

Facebook: PNP Charcoal

Instagram: PNP Charcoal

Email: info@pnpglobalsupply.com