In today’s highly competitive global market, charcoal export business is no longer just about selling raw charcoal at a low price. International buyers are increasingly looking for flexible solutions that allow them to build their own brands, control product quality, and adapt quickly to market demand. This is where OEM (Original Equipment Manufacturer) plays a crucial role in modern charcoal exports.

OEM has become a preferred model for importers, distributors, and BBQ brands worldwide, especially for products such as hardwood lump charcoal and other kinds of charcoal tailored to specific markets. Understanding how OEM works can help businesses unlock long-term growth opportunities in the global charcoal industry.

What Does OEM Mean in the Charcoal Export Business?

In simple terms, OEM refers to a manufacturing arrangement in which the producer makes charcoal products according to the buyer’s specifications, while the buyer sells those products under their own brand. In the charcoal export business, OEM usually covers production, quality control, and packaging, while the importer focuses on branding, marketing, and distribution.

This model allows buyers to offer customized charcoal products without owning a factory or managing a charcoal warehouse in the country of origin. Whether the product is hardwood lump charcoal for professional BBQ or packaged charcoal for retail markets, OEM provides flexibility and scalability.

Why OEM Is Becoming a Key Trend in Charcoal Export Business

The global BBQ and food service markets are becoming more brand-driven. Buyers are no longer satisfied with generic products; they want unique charcoal brands that stand out in quality, appearance, and performance. OEM makes this possible by enabling full customization of products and packaging.

Another important factor is the growing diversity of demand. Different regions prefer different kinds of charcoal, depending on cooking habits, climate, and price sensitivity. OEM allows charcoal exporters to tailor products to each market without increasing operational complexity.

Common OEM Models in Charcoal Export Business

OEM in charcoal exports often goes beyond basic manufacturing. Many suppliers now offer integrated solutions that include raw material selection, production, packaging, and export logistics.

One common approach is OEM production based on buyer-defined quality standards, especially for premium hardwood lump charcoal. Another popular option is OEM packaging, where products are packed according to specific weights such as kg charcoal bbq formats for retail or food service use. Many international clients also choose OEM to develop private-label charcoal brands for their domestic markets.

OEM for Hardwood Lump Charcoal and Other Kinds of Charcoal

Hardwood lump charcoal remains one of the most in-demand products in the global charcoal export business due to its high heat output, clean burn, and natural composition. Through OEM, buyers can specify lump size, burning characteristics, ash content, and even the visual appearance of the charcoal.

Beyond hardwood lump charcoal, OEM can be applied to many other kinds of charcoal, allowing exporters to serve a wide range of BBQ and commercial cooking needs. This flexibility helps buyers expand their product portfolios while maintaining consistent quality across different markets.

The Importance of Charcoal Packages in OEM Exports

In international trade, charcoal packages are not just about protection; they are a key part of branding and marketing. Packaging design, material, and size strongly influence how charcoal brands are perceived by end consumers.

OEM enables buyers to fully customize charcoal packages, including bag size, labeling, and structural design. Offering multiple kg charcoal bbq options helps brands target different customer segments, from household users to professional restaurants and BBQ chains.

How Charcoal Pack Price Is Determined in OEM Projects

Charcoal pack price in an OEM model depends on several factors. The type of charcoal, especially premium hardwood lump charcoal, plays a major role in cost structure. Packaging materials, printing quality, and bag size also have a direct impact on pricing.

Storage and logistics costs, including handling at a charcoal warehouse, are another important element. One advantage of OEM is that buyers can use the manufacturer’s warehouse facilities, reducing capital investment and improving cash flow efficiency in their charcoal export business.

Do You Need a Charcoal Warehouse When Working with OEM?

One major benefit of OEM is that buyers do not need to own or operate a charcoal warehouse in the country of origin. Most OEM manufacturers already have export-ready storage facilities that meet international standards.

This arrangement is especially attractive for new or expanding charcoal brands. Instead of investing heavily in infrastructure, buyers can focus on sales, marketing, and market expansion while relying on the OEM partner for production and storage.

Benefits and Risks of OEM in Charcoal Export Business

OEM offers clear advantages for companies involved in charcoal export business. It allows faster market entry, flexible product customization, and efficient brand building. Buyers can launch their own charcoal brands without the burden of manufacturing operations.

However, OEM also comes with potential risks if the supplier is not carefully selected. Quality consistency, production capacity, and transparency in charcoal pack price must be closely monitored. A reliable OEM partner is essential to long-term success.

Who Should Choose OEM in the Charcoal Export Business?

OEM is ideal for importers, distributors, and BBQ retailers who want private-label products without managing production. These businesses often seek to diversify kinds of charcoal, offer competitive charcoal packages, and optimize operational costs.

For established BBQ brands in developed markets, OEM provides a way to focus on brand development and distribution while outsourcing production to experienced charcoal manufacturers.

How to Choose a Reliable OEM Charcoal Supplier

Selecting the right OEM partner is critical. A trustworthy supplier should have proven experience in charcoal export business, stable production of hardwood lump charcoal, and the ability to handle different kinds of charcoal efficiently.

Equally important are packaging capabilities, professional handling of charcoal packages, and a well-managed charcoal warehouse that supports consistent export operations.

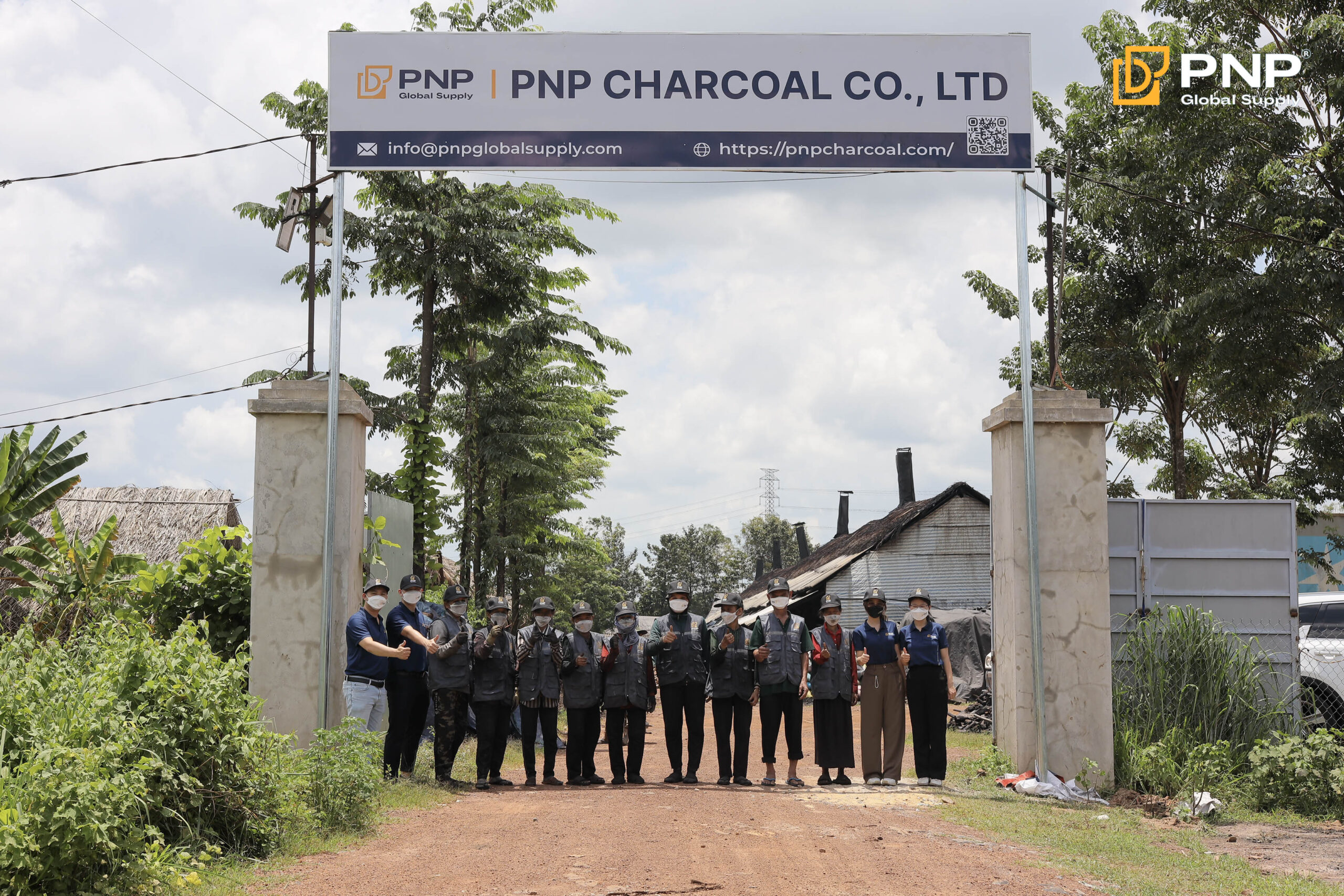

PNP Charcoal provides high-quality charcoal with reliable OEM solutions, backed by professional export experience, stable hardwood lump charcoal production, and flexible packaging options. With well-managed warehouses and strict quality control, PNP Charcoal ensures consistent supply for global markets. Visit our website at PNP Charcoal to explore premium charcoal products and choose the right solution for your brand.

Conclusion

OEM is no longer just a manufacturing option; it is a strategic tool for scaling and differentiating a charcoal export business. By enabling customization, brand ownership, and cost efficiency, OEM helps businesses compete effectively in international markets.

As global demand for high-quality charcoal continues to grow, companies that understand and leverage OEM models will be better positioned to build strong charcoal brands and achieve sustainable long-term success.

________________________________

Contact us for more information

Facebook: PNP Charcoal

Instagram: PNP Charcoal

Email: info@pnpglobalsupply.com