Kaya charcoal has become one of the most sought-after charcoal types in today’s BBQ and grilling market. Known for its exceptional hardness, long burning time, and extremely low smoke output, kaya charcoal is widely used in professional kitchens, high-end BBQ restaurants, and international markets that require consistent heat performance. As demand continues to rise, more suppliers and manufacturers are looking to understand how to make kaya charcoal properly—especially how to produce high-quality kaya charcoal that meets strict export standards.

This guide provides a full, detailed explanation of how to make kaya charcoal from raw wood to finished product. It also includes essential subtopics such as make wood charcoal, make charcoal, charcoal factory process, Vietnamese charcoal, and its comparison with traditional lumpwood charcoal.

Introduction to Kaya Charcoal

Kaya charcoal is a premium form of hardwood charcoal that is favored for its durability, density, and heat retention. Unlike ordinary lumpwood charcoal, kaya charcoal is produced using a specific carbonization method that results in a harder structure and a longer burning duration. Because of these outstanding characteristics, it is considered one of the highest-quality charcoal types available in many Asian and Middle Eastern markets.

With the global demand for Vietnamese charcoal growing steadily, understanding how to make charcoal the right way becomes essential for manufacturers and new suppliers entering the industry.

Key Features of Kaya Charcoal

Kaya charcoal stands out because of its unique combination of strength, clean burning, and stability. When compared to regular lumpwood charcoal, kaya charcoal burns significantly longer, produces very little ash, and generates almost no smoke. This makes it ideal for indoor BBQ restaurants, Korean grills, yakiniku shops, and export markets where smoke control is strictly regulated.

Another strong advantage is its uniform shape and high density. Well-produced kaya charcoal has a shiny black surface, metallic sound when tapped together, and high carbon content. These features allow it to outperform typical Vietnamese charcoal varieties such as eucalyptus or longan charcoal.

Preparation Before Making Kaya Charcoal

Before learning exactly how to make kaya charcoal, it’s important to prepare the right materials and equipment. High-quality kaya charcoal begins with carefully selected hardwood. Manufacturers usually choose dense, mature wood because it delivers higher fixed carbon after carbonization.

The wood used for make wood charcoal must be clean, free from mold, and cut into consistent sizes. Moisture plays a crucial role—wood must be dried or kiln-dried until its moisture level is low enough to carbonize effectively.

Inside a professional charcoal factory, preparation also involves organizing tools such as carbonization kilns, metal or brick furnaces, cooling chambers, and storage areas. Proper preparation ensures the process flows smoothly and the final kaya charcoal meets export-grade standards.

Step-by-Step Process: How to Make Kaya Charcoal

This is the most important part of producing high-quality kaya charcoal. The process requires skill, accuracy, and constant temperature control. Below is a detailed breakdown of how to make charcoal specifically for kaya-grade production.

Selecting and Treating the Hardwood

The first step to make wood charcoal is choosing the right type of hardwood. Strong, mature hardwood produces better kaya charcoal because it contains more lignin and density. After selecting the wood, workers cut it into equal lengths to ensure consistent carbonization.

The wood is then dried—either naturally under the sun or in a drying chamber. Proper drying prevents cracking, excessive smoke, and energy loss during carbonization. If the wood is too wet, the resulting charcoal will be weak and crumbly.

Loading the Kiln

When the wood is ready, it is loaded into the kiln inside the charcoal factory. The wood must be arranged tightly but with enough airflow between layers to allow heat to circulate evenly. The arrangement of the wood directly affects the quality of the final kaya charcoal, so experienced workers are needed for this step.

Depending on the size of the kiln, several tons of hardwood can be loaded at once.

Starting the Carbonization Process

To make charcoal, the kiln is heated gradually. At first, a small fire is started using scrap wood or small pieces of lump charcoal. Once the kiln reaches the required temperature, its openings are slowly closed to create an oxygen-limited environment.

This is the foundation of kaya charcoal production. Instead of burning, the wood undergoes pyrolysis—thermal decomposition without oxygen. This removes moisture, sap, and gases while preserving carbon.

Controlling Heat and Carbonization Time

The temperature inside the kiln must be kept between 400°C and 600°C to achieve high-quality kaya charcoal. If the temperature is too low, the carbonization will be incomplete. If it is too high, the wood may ignite and turn to ash.

During this stage, workers observe the color of the smoke coming from the chimney. Dark smoke means the wood is still releasing moisture and gases. As it becomes lighter, the carbonization process is nearing completion.

This stage separates ordinary lumpwood charcoal from premium kaya charcoal. Consistent temperature and slow carbonization create a denser, harder final product.

Heat-Holding Stage for Kaya Density

Once the main carbonization is complete, the kiln temperature is held steady for several more hours. This “heat-holding” stage increases the density of the charcoal and enhances its burning performance. It is one of the key reasons kaya charcoal has such a long burning time compared to other types of Vietnamese charcoal.

Cooling the Kiln

After carbonization, the kiln must be sealed entirely and allowed to cool naturally for 24 to 48 hours. Introducing oxygen too early will cause the charcoal to ignite inside the kiln. Natural cooling helps stabilize the charcoal and preserves its structure.

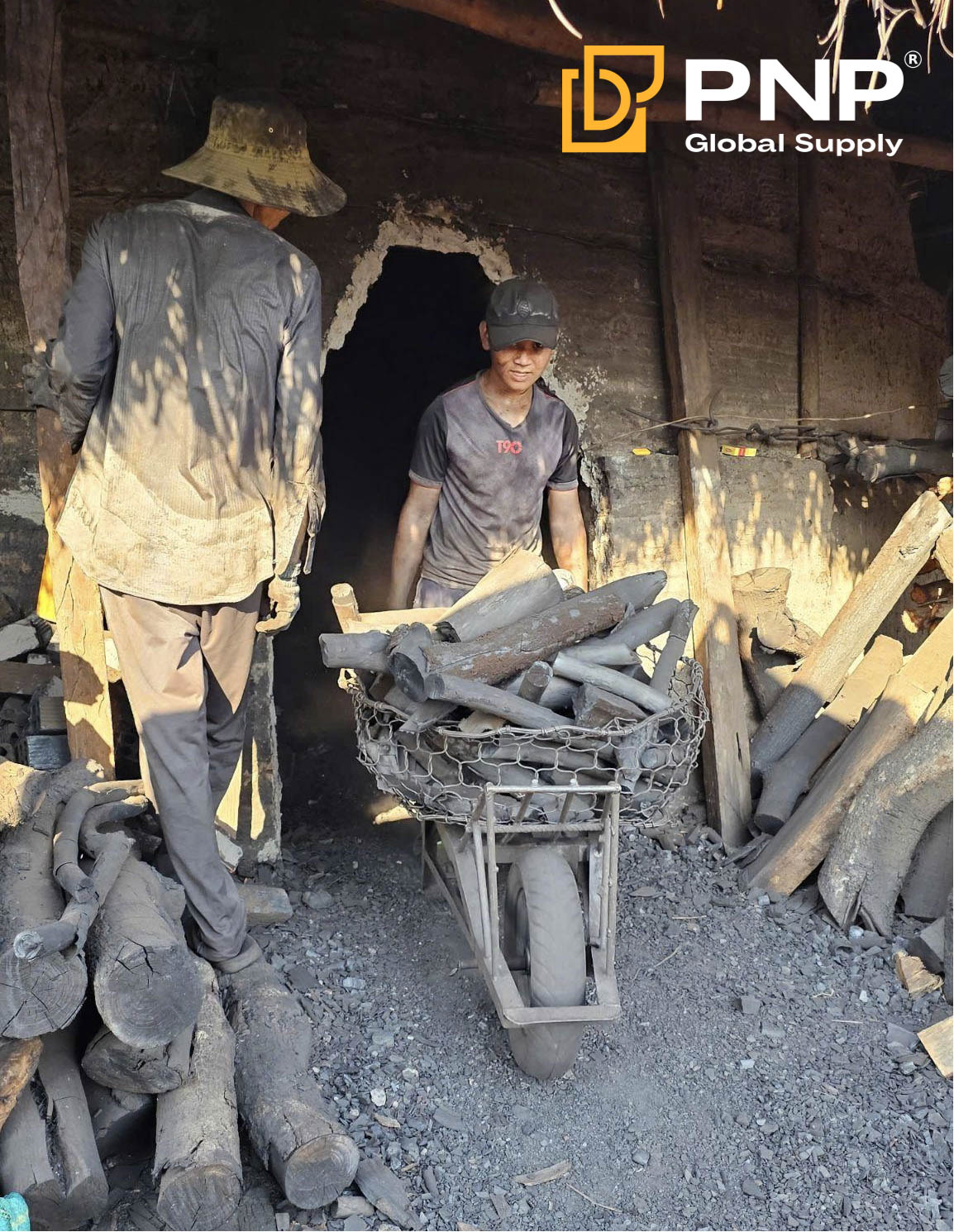

Collecting and Sorting the Charcoal

Once the kiln is completely cool, workers unload the charcoal and begin sorting it by size and shape. Export markets prefer large, uniform pieces, so kaya charcoal is graded based on weight and size. Dust and small fragments are removed.

High-quality kaya charcoal should be metallic black with a glossy finish, extremely hard, and produce a ringing sound when struck.

Packaging and Storage

To maintain elite quality, kaya charcoal must be packaged properly. Most charcoal factory operations use PP bags, kraft paper bags, or carton boxes to keep the charcoal dry and clean.

The storage area must be cool and dry. Charcoal that absorbs moisture will lose density and burn poorly. Proper packaging ensures that kaya charcoal retains its shelf life and performance during export.

If you want to learn more about export-standard charcoal packaging options, check out the article below: TOP 4 TYPES OF CHARCOAL PACKAGING FOR EXPORT

Where to Buy or Produce Kaya Charcoal

Vietnam is currently one of the leading producers of high-grade charcoal. Many factories specialize in kaya charcoal, lumpwood charcoal, and other forms of Vietnamese charcoal for export. Collaborating with a reputable factory ensures stable quality, competitive pricing, and consistent supply—key factors for importers and distributors.

PNP Charcoal provides premium-quality kaya charcoal and other types of Vietnamese charcoal, crafted for long-lasting heat, low smoke, and consistent performance. Whether you are running a high-end BBQ restaurant or sourcing for export, our charcoal ensures reliability and superior results every time. Visit our website today to explore our full range of products and learn how PNP Charcoal can meet your grilling and business needs.

Conclusion

Understanding how to make kaya charcoal is essential for anyone wanting to supply or produce premium charcoal for BBQ, restaurant, or export markets. From selecting hardwood to managing kiln temperature, every step of the process affects the final product. When produced correctly, kaya charcoal delivers exceptional heat, long burn time, and minimal smoke—making it superior to standard lumpwood charcoal and many other types of Vietnamese charcoal.

If you want further guidance on how to make charcoal, build a charcoal factory, or source premium kaya charcoal directly from Vietnam, feel free to request a customized consultation.

________________________________

Contact us for more information

Facebook: PNP Charcoal

Instagram: PNP Charcoal

Email: info@pnpglobalsupply.com