When importers walk down the barbecue aisle or scroll through an online marketplace, they are not only comparing charcoal quality but also the size and sturdiness of each bag. In export trade, the weight that ends up printed on the kraft sack or woven PP bag can be the line between a fast‑moving product and one that is left on the pallet. Because global distributors search the web using phrases like “kg charcoal BBQ” understanding which weights resonate with each destination market has become a decisive skill for producers. The goal of this article is to explain how choosing the right bag weight and the right charcoal packaging style will help you control logistics costs, satisfy retail buyers, and ultimately boost sales.

Why Bag Weight Matters in Charcoal Export

First, shipping cost is calculated by weight and volume. A carefully selected bag size can maximize container fill rates while keeping every ton within a carrier’s preferred break points, which lowers the cost‑per‑kilogram and preserves margins. Second, consumer convenience is critical: a family spending the weekend at the beach wants a single lift‑able sack, whereas a restaurant prefers a bigger unit to minimize unpacking time. Finally, packaging integrity depends on weight. A kraft three‑ply sack with an internal polyethylene liner can comfortably handle up to 5 kg charcoal without tearing, but if you squeeze 20 kg into the same material, the bottom seam may burst on impact. Aligning weight, material strength, and user expectations ensures the product arrives intact and still attractive on the shelf.

Popular Charcoal Bag Weights for the BBQ Market

Charcoal 1 kg – the grab‑and‑go option

The smallest format speaks directly to campers, picnic lovers, and apartment dwellers with limited storage. A compact charcoal 1 kg pouch fits easily in a backpack, meets airline cabin weight limits for domestic flights in some countries, and can be displayed in check‑out zones where impulse buys occur. Because moisture control is essential at low weights, most producers choose laminated paper with a fold‑over top and a small carry handle. The modest volume also lets importers offer multipack promotions—three one‑kilogram pouches bundled together still weigh less than the standard 5 kg charcoal bag but feel like a better deal to the end customer.

5 kg Charcoal – the global bestseller

Across Europe, North America, and Oceania, the 5 kg charcoal bag dominates supermarket and DIY store shelves. Retail buyers praise this size because it balances shelf density, consumer convenience, and price perception. Families can lift it easily, yet it contains enough fuel for two weekend barbecues. For exporters, this sweet spot means higher pallet counts: one 40‑foot container can usually carry about 4 % more net weight when filled with five‑kilogram sacks compared to ten‑kilogram sacks due to better void fill. To protect that value, a kraft three‑ply design with an optional PE liner is recommended. Branding can be printed in up to eight colors, providing both eye‑catching graphics and precise barcode readability. It is no coincidence that keyword tools report “5 kg charcoal” as one of the highest‑volume search queries in the sector.

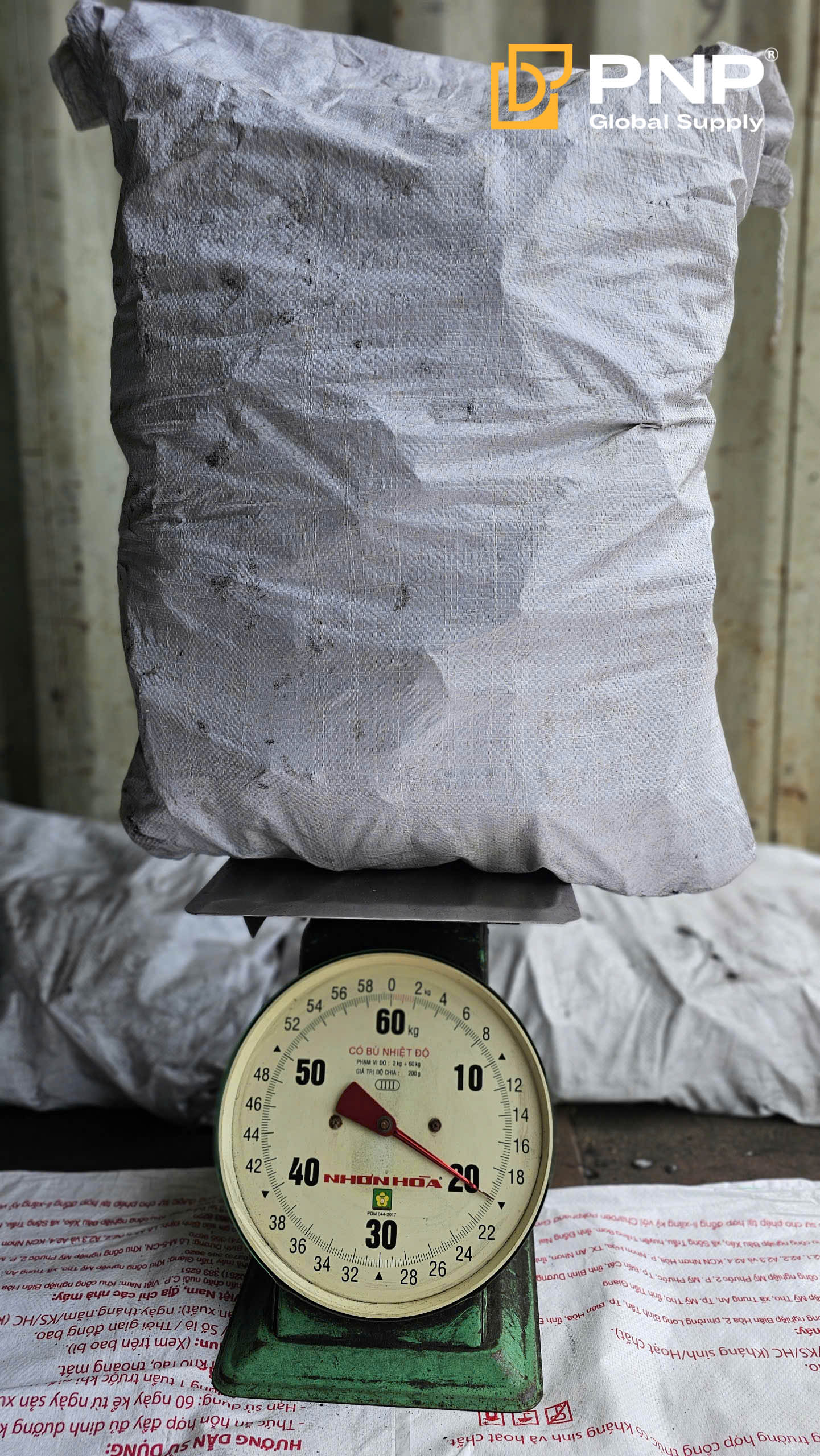

10 kg–20 kg Charcoal Packages – for food service and wholesalers

Professional kitchens, shisha lounges, and regional distributors buy in bulk. They need longer burn times in large grills and want to reduce ordering frequency. Charcoal packages in the 10 kg to 20 kg range answer that need. At this weight, durability becomes paramount. Exporters often switch from kraft to woven polypropylene (PP) with a laminated outer layer, which resists punctures and humidity inside container yards in tropical ports. Double‑stitched bottoms or heat‑sealed seams prevent accidental spillage. While a twenty‑kilogram unit may sound heavy, forklifts or small hand cranes in warehouses manage the lifting—saving staff time and minimizing packaging scrap. Having the SKU in this category also positions a producer to capture private‑label food‑service contracts that require high annual volumes.

Charcoal Packaging Standards Every Exporter Should Meet

International buyers increasingly audit suppliers for traceability and sustainable sourcing. Regardless of bag weight, every charcoal package should carry clear information: wood species or raw material, net weight in both imperial and metric units (for example, “5 kg / 11 lb”), production lot code, country of origin, and any relevant eco‑certifications. For European retail chains, EN1860‑2 safety labeling is advised. Kraft three‑ply sacks with a 25‑micron PE liner remain the benchmark for hardwood lump charcoal. Woven PP bags are favored in high‑humidity destinations and can be printed via BOPP lamination to achieve retail‑grade graphics. If you supply coconut briquettes or extruded hex sticks, consider a double‑wall carton placed inside a master PP bag to combine stiffness with water resistance. Good charcoal packaging is not just about appearance—it protects calorific value and fixed carbon percentages by keeping out ambient moisture.

Learn more about charcoal export packaging in the article below: TOP 4 TYPES OF CHARCOAL PACKAGING FOR EXPORT

Matching Bag Weight to Export Destinations

In the European Union and the United Kingdom, grilling is often centered around weekend barbecues in small home gardens. Retail chains like Tesco and Carrefour typically prefer bags between 3 and 5 kilograms, as they fit neatly into shopping trolleys and compact car trunks.

The Gulf region, especially the UAE and Saudi Arabia, favors larger gatherings and longer cooking sessions. Importers in Jebel Ali, Dubai, often request 10 to 20 kg charcoal sacks, as they supply both households hosting big feasts and restaurants grilling meat daily.

Markets like Japan and South Korea value cleanliness and well-designed packaging. With limited living space, consumers often grill on balconies or use portable stoves. As a result, brands offering 1 kg or 3 kg charcoal bags with resealable zippers and minimalist black-and-white designs are gaining traction.

PNP Charcoal offers a wide range of packaging sizes from 1kg to 20kg, tailored to export destinations like Europe, the Middle East, and East Asia. Visit our website: pnpcharcoal to explore product details and find the right kg charcoal BBQ solution for your market.

Conclusion

Choosing the right bag weight is more than a cosmetic decision—it is a strategic tool to sharpen your competitive edge. The global data are clear: 5 kg charcoal remains the volume leader in mainstream retail, 1 kg charcoal satisfies the mobility craze of outdoor adventurers, and 10 kg–20 kg charcoal packages secure the loyalty of restaurants and wholesalers.

In an export arena where margins hinge on logistics efficiency and brand trust, the seemingly simple choice of bag weight can propel your kg charcoal BBQ offering from a commodity to a category leader.

________________________________

Contact us for more information

Facebook: PNP Charcoal

Instagram: PNP Charcoal

Email: info@pnpglobalsupply.com