Charcoal briquettes are the next-generation fuel manufactured from organic materials such as sawdust, coconut shell, and agricultural by-products, combined with natural binders. Introduced in the United States in 1920, they quickly became a global trend due to their ability to replace traditional lump charcoal. In Vietnam, charcoal briquettes are highly favored for BBQ cooking, drying industries, and boilers because of their outstanding performance and eco-friendly characteristics.

Why do Charcoal Briquettes dominate the market?

- Competitive Pricing: More cost-effective than lump charcoal and natural wood charcoal.

- Steady Burning: Provides stable, low-smoke combustion ideal for enclosed spaces.

- Environmental Benefit: Reduces CO₂ emissions by 50% compared to conventional charcoal burning.

Technical specifications of Charcoal Briquettes

Quality determinants

- Moisture Content: Below 8% – ensures even burning with minimal smoke.

- Carbon Content: Over 70% – delivers high heat (7,000 – 8,000 kcal/kg).

- Binder: Cassava starch or wood flour – safe when burned.

Standard technical parameters

| Shape | Cibe/Finger/Hexagon |

| Size | Charcoal sawdust – Diameter: 4-5cm- Length: 15-20cm Charcoal coconut – Diameter: 2.5×2.5×2.5cm | 2x2x2cm |

| Burning Duration | 3-4 hours per 1 kg |

| Ash Content | < 5% |

| Heat Value | 7.900 kcal/kg |

| Packing | 1200-1400 FOB (USD/ton) |

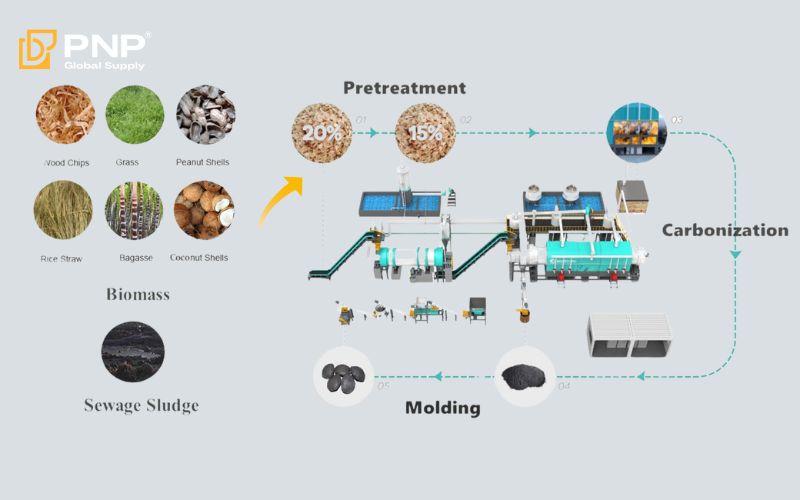

Modern manufacturing technology

PNP Charcoal employs a closed hydraulic pressing process that meets ISO 14001 standards:

- Material Grinding: Sawdust and coconut shell are thoroughly cleaned and sun-dried.

- Binder Mixing: A ratio of 85% raw materials to 15% starch.

- Molding: Using 1,500-ton pressure to produce uniform briquettes.

- Product Drying: At 250°C to remove residual moisture.

Outstanding Benefits of Using Charcoal Briquettes

- Optimal Burning Efficiency:

-

-

- Maintains stable heat for 3-4 hours, making it ideal for grilling meats and seafood.

- Produces minimal ash, ensuring easy post-use cleaning.

-

- Cost Savings:

-

-

- Reduces fuel consumption by 30% compared to wood charcoal.

-

- Environmental Protection:

-

-

- Utilizes agricultural by-products, reducing the need for deforestation.

- Odorless and low in smoke, ensuring respiratory safety.

-

- Versatile Applications:

-

-

- Suitable for family BBQs, restaurant grill.

- Compatible with lump charcoal stoves, clay ovens, and kamado grills.

-

- Absolute Safety:

-

- No sparks produced, significantly reducing the risk of fire or explosion.

Comparison of Charcoal Briquettes with other charcoal types

| Charcoal Type | Charcoal Briquettes | Traditional Wood Charcoal |

| Burning Duration | 3-4 hours | 1-2 hours |

| Heat Value | 7.900 kcal/kg | 7.504 kcal/kg |

| Ash Content | < 5% | < 5% |

| Price | 650 – 1400 USD/ton | 350 – 650 USD/ton |

Production process & how to identify high-quality Charcoal Briquettes

Composition

- 80-85%: Sawdust, and coconut shells serve as the primary energy source.

- 10-15%: Cassava starch or wood flour acts as the binder, providing hardness and durability.

- 5%: Anti-moisture additives (typically white clay) are added to reduce water absorption, thereby extending shelf life and maintaining product quality.

How to identify quality briquettes

- Color: Glossy black and no signs of cracks.

- Hardness: Should not crumble when dropped from a height of 1 meter.

- Burning Aroma: Emits a light woody fragrance without an overly smoky smell.

A thorough inspection of these factors ensures you select charcoal briquettes with excellent burning efficiency and safety.

Conclusion

Charcoal Briquettes offer a “3-in-1” solution: cost savings, environmental friendliness, and outstanding performance. This product meets a wide range of needs from household use to commercial applications, especially when combined with a Binchotan charcoal grill for a premium BBQ experience.

Contact us now at Hotline: 0888 521 159 or visit pnpcharcoal.com for expert consultation!